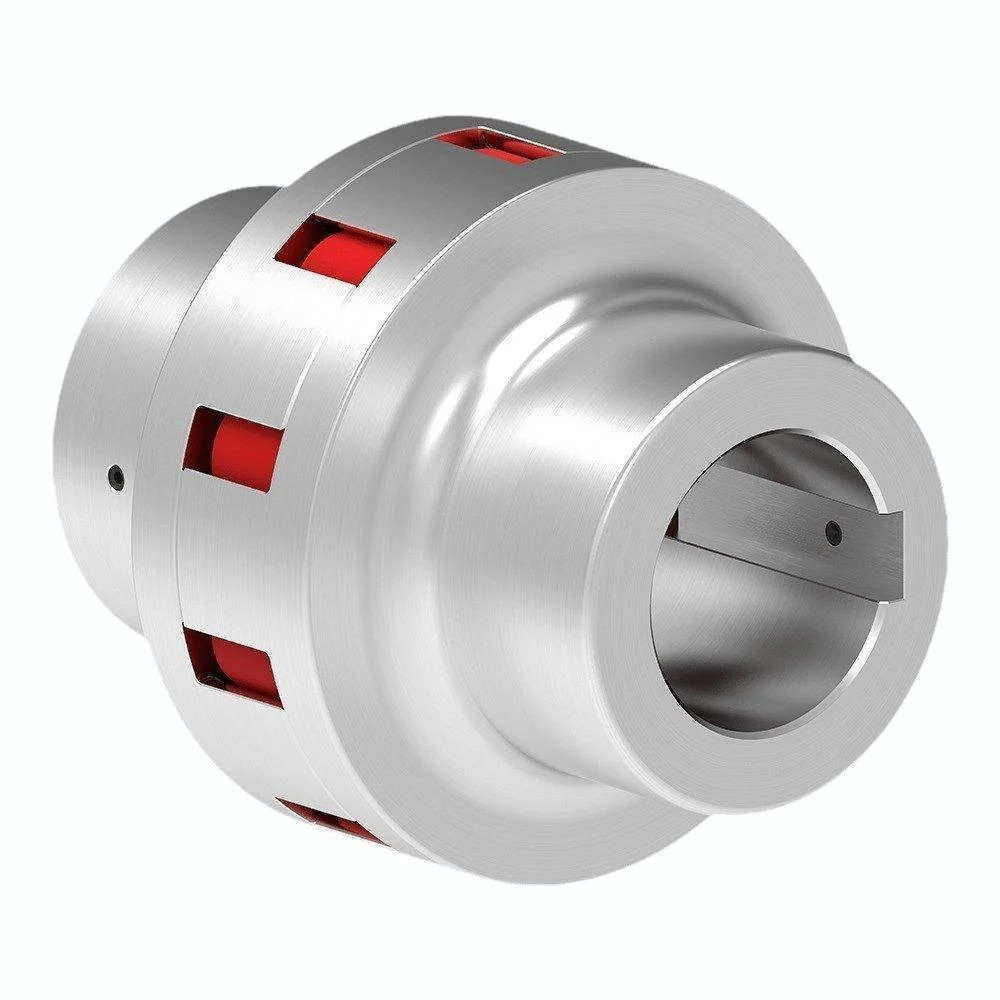

Rotex Jaw Coupling

Rotex Jaw Coupling Specification

- Head Code

- Round

- Usage

- Industrial

- Material

- Aluminum

- Inner Diameter

- 2 Millimeter (mm)

- Color

- Silver

- Surface Treatment

- Polished

Rotex Jaw Coupling Trade Information

- Minimum Order Quantity

- 2 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

About Rotex Jaw Coupling

Get your hands on the exceptional Rotex Jaw Coupling, offering a sizzling combination of durability and performance. Utilise its outstanding head codeRound and precise inner diameter of 2 mm, perfectly polished in noble silver. Crafted from high-grade aluminum, this coupling stands out for industrial usage and ensures reliable functionality. Offered by renowned distributors, manufacturers, suppliers, and traders across India, this coupling delivers impressive quality and remarkable versatility. Choose Rotex Jaw Coupling for noble results that enhance productivity and operational excellence in your industrial setups.

Wide-Ranging Applications of Rotex Jaw Coupling

Rotex Jaw Coupling is utilised extensively in industrial environments as a critical mechanical connecting component. It is used for transmitting torque in automation systems, pumps, and conveyors with application media including air, hydraulic fluids, and lubricants. This coupling excels in places that demand flexibility and high performance, proving indispensable as a torque-transmitting and vibration-damping unit across varied industrial sectors.

Rotex Jaw Coupling Sample Policy and Delivery Assurance

To initiate your procurement process, request a quotation for Rotex Jaw Coupling sampleseach backed by relevant certifications. The sample packing & dispatch process ensures product integrity and swift movement. Items are carefully packed and dispatched upon order confirmation, with delivery time tailored to customer location and order volume. Customers can rely on timely, secure delivery, reinforcing the suppliers commitment to quality and satisfaction.

Wide-Ranging Applications of Rotex Jaw Coupling

Rotex Jaw Coupling is utilised extensively in industrial environments as a critical mechanical connecting component. It is used for transmitting torque in automation systems, pumps, and conveyors with application media including air, hydraulic fluids, and lubricants. This coupling excels in places that demand flexibility and high performance, proving indispensable as a torque-transmitting and vibration-damping unit across varied industrial sectors.

Rotex Jaw Coupling Sample Policy and Delivery Assurance

To initiate your procurement process, request a quotation for Rotex Jaw Coupling sampleseach backed by relevant certifications. The sample packing & dispatch process ensures product integrity and swift movement. Items are carefully packed and dispatched upon order confirmation, with delivery time tailored to customer location and order volume. Customers can rely on timely, secure delivery, reinforcing the suppliers commitment to quality and satisfaction.

FAQs of Rotex Jaw Coupling:

Q: How is the Rotex Jaw Coupling used in industrial settings?

A: The Rotex Jaw Coupling is used to efficiently transmit torque between shaft systems in industrial machinery, ensuring reliable connection and reduced vibration in applications such as pumps, conveyors, and automation units.Q: What benefits does the polished aluminum construction provide?

A: The polished aluminum construction offers outstanding corrosion resistance, improved durability, and lightweight handling, contributing to the couplings exceptional longevity and smooth performance in rigorous industrial environments.Q: When can customers expect delivery after placing an order?

A: Delivery timelines depend on the customers location and the quantity ordered, but the supplier prioritises swift packing & dispatch to ensure products are dispatched promptly and reach clients within the agreed delivery schedule.Q: Where can Rotex Jaw Coupling be installed?

A: Rotex Jaw Coupling can be installed in a range of industrial machinery wherever reliable shaft connection and torque transmission are required, such as in automating systems, fluid pumps, and power conveyance lines.Q: What is the process for requesting samples and quotations?

A: Customers should contact the supplier and request a quotation specifying their requirements. Sample packing & dispatch will then be completed, ensuring integrity and prompt sample shipment for evaluation.Q: Which application media is suitable for this coupling?

A: The Rotex Jaw Coupling operates with multiple application media, including air, hydraulic fluids, and lubricants, making it highly versatile for various industrial processes.

Price 431 INR/ Piece

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Couplings Category

Lovejoy Tyreflex Coupling

Price 251 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron

Usage : Structure Pipe

Head Code : Round

Color : Black

Servo Encoder Coupling

Price 145 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Aluminum

Usage : Industrial

Head Code : Round

Color : Silver

Ktr Radex Nn Lamina Disc Coupling N60 N70 N80 N95 N105 N115 N135 N136 Nana 1 Nnz Nana 4 Nnw Nana 3

Price 4510 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Usage : Industrial

Head Code : Round

Bauer Type Coupling

Price 251 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Usage : Industrial

Head Code : Round

Color : Silver

Send Inquiry

Send Inquiry